Unilux AM

Unilux Developed an innovative bent water tube boiler design. This boiler is used for commercial, institutional, and industrial heating / process applications. Applications include hot water, high pressure steam, low presume steam, high temperature hot water, waste heat, thermal fluid, and recently, industrial modular.

Unilux is the world’s original 5 pass forced draft bent tube boiler. With over thirty years of manufacturing and operational experience in just about every industry requiring boilers, Unilux stands alone as the most pristine, highly engineered, ultimate quality boiler in it’s class. While the product speaks volumes, our success is our people; many with over 25 years at Unilux, we take enormous pride in every unit we manufacture. From immediate response to inquiries, performance data, drawings, product description and assistance with proper selection, everyone at Unilux has one important goal in mind…customer satisfaction. Unilux QA/QC boasts a stringent, internal program that emphasizes employee responsibility to safety, product and quality performance.

Construction for all Unilux boilers starts with the vessel. All vessel material is controlled, ASME compliant material. Generous upper and lower drums are joined with large, external downcomer(s) allowing for maximum internal circulation. Tubes are a minimum 1.5” diameter, SA 178 Grade “A” material. Tube sizes up to 2.5” diameter are used for larger boilers. The Unilux housing is the most rigid available. Individual steel panels are manufactured with 11 gauge steel and reinforced by bending and welded stiffeners throughout. Refractory design is exclusive to Unilux. We utilize a three tier pour of different tolerance refractory for ultimate performance. All Unilux refractory is warranted for 5 years as standard. Finished insulated jacket panels are scratch resistant, polyester impregnated powder coat. Thermal losses from housing and jacket are 0.5 percent. The completed enclosure allows for up to +5” water column gas side pressure. All Unilux boilers are available with fuel burning equipment and control systems as desired.

Safety is paramount at Unilux. Every Unilux boiler has been engineered to be the safest, most efficient product available in its class.

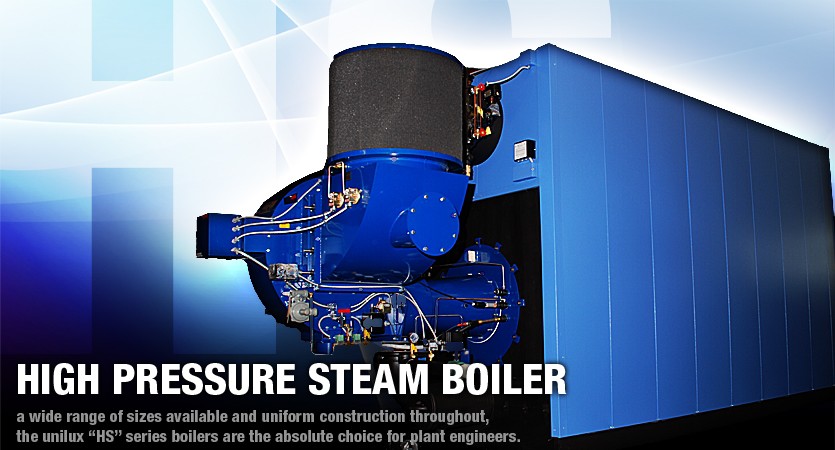

High Pressure Steam HS Series

With the greatest range of sizes available and uniform construction throughout, Unilux “HS” Series boilers are the absolute choice for plant engineers. The exclusive Unilux stainless steel knockout baffle travels the entire length of the steam drum for maximum steam quality at the outlet. The Unilux High Pressure Steam boiler delivers unsurpassed quality of steam up to 99.9%. All Unilux steam boilers boast rapid steam generating times of approximately 15 minutes to a head of steam from a cold start and will respond to swing load conditions like no other boiler on the market. Standard construction is ASME Section I at 150 PSI. Pressures to 900 PSI available. Unilux high pressure steam boilers are also available as “FE”; field erect units which require absolutely no welding on site for assembly. All Unilux boilers have simple to remove and replace access panels and tube change is done without any welding or rolling (ferrule-fit models only). Double inspection / cleanout ports in all drums, industry trusted operating / level and pump controls mounted in a manner that makes daily boiler inspections simple. Factory packaged units are standard with the required ASME valve / piping package and is wholly tested at our facility and witnessed by an Authorized ASME Inspector prior to completion. Operating efficiencies are 81% without any external devices, up to 84% with our economizer package. Use Unilux high pressure steam boilers for central heating, process, autoclave, injection process, main plant distribution systems or anywhere clean, dry steam is required at pressures above 15 PSI.

Low Pressure Steam Boiler LS Series

For space heating applications, or wherever low pressure steam (up to 15 PSI) is needed, trust the Unilux “LS” series low pressure steam boiler. The exclusive Unilux stainless steel knockout baffle travels the entire length of the steam drum for maximum steam quality at the outlet. Standard construction is ASME Section IV. Unilux low pressure steam boilers are also available as “FE”; field erect units which require absolutely no welding on site for assembly. All Unilux boilers have simple to remove and replace access panels and tube change is done without any welding or rolling. Double inspection / cleanout ports in all drums, industry trusted operating / level and pump controls mounted in a manner that makes daily boiler inspections simple. All units are inspected by a third party inspection agency at least twice during the construction process to insure the best product, every time. All tubes are minimum 1.5” OD, SA178 Grade “A” material. All Unilux steam boilers boast rapid steam generating times of approximately 15 minutes to a head of steam from a cold start and will respond to swing load conditions like no other boiler on the market.

Please contact us if you would like more information on the Unilux AM Boilers